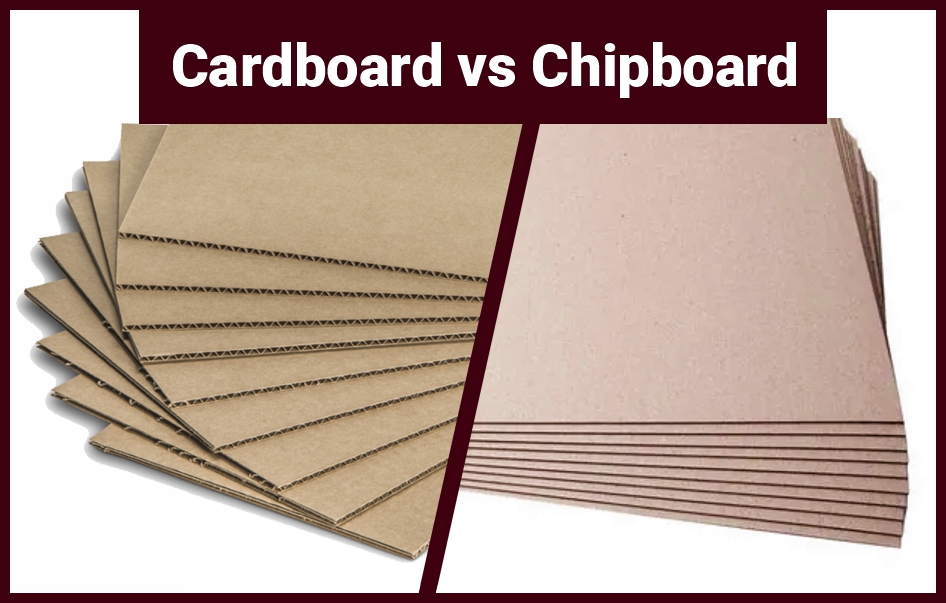

When it comes to packaging materials, the debate between chipboard and cardboard has been gaining momentum. Each material possesses distinct qualities suited to specific needs. Let’s explore the features of both to determine which one reigns supreme for your specific packaging requirements:

Chipboard:

Pros:

Eco-conscious: Chipboard is crafted from recycled paper and cardboard materials, making it a sustainable choice for those seeking to reduce their environmental footprint.

Printability: It provides a superb canvas for printing, delivering a consistently smooth surface that enhances the sharpness and vibrancy of your designs and labels.

Lightweight: Chipboard’s lightweight nature is beneficial in applications requiring weight minimization, such as crafting product packaging.

Chipboard and cardboard are both types of paperboard, but chipboard is generally considered better than cardboard for slip sheets in certain applications.

While chipboard has many advantages, it's important to note that the choice between chipboard and cardboard depends on the specific needs of the application. Cardboard also has its own set of benefits, including lightweight properties, recyclability, and cost-effectiveness. Your selection should be based on factors such as the intended use, environmental considerations, and budget constraints.

Here are some reasons why chipboard may be preferred over cardboard for slip sheets:

Strength and Durability:

Chipboard is typically denser and more rigid than standard cardboard. This increased density provides better strength and durability, making chipboard slip sheets less prone to bending or breaking during handling and transportation.

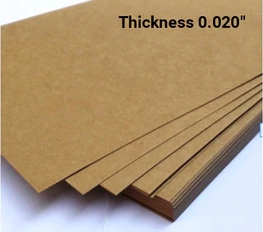

Consistency in Thickness:

Chipboard manufacturing processes often result in a more consistent thickness compared to cardboard. Consistency is crucial for slip sheets to maintain structural integrity and perform reliably in automated handling systems.

|

|

|

|

Moisture Resistance:

Chipboard tends to have better resistance to moisture than cardboard. This is important for slip sheets, especially in environments where exposure to humidity or moisture is a concern. Chipboard is less likely to warp or degrade in damp conditions.

Stiffness and Stacking Strength:

Chipboard generally exhibits higher stiffness and stacking strength compared to cardboard. This is advantageous when slip sheets are used to support loads during stacking, helping to prevent the sheets from collapsing under the weight of the products.

Customization and Specialty Grades:

Chipboard is available in various grades and can be customized to meet specific requirements. Specialty grades with enhanced features, such as increased stiffness or moisture resistance, can be chosen based on the intended application.

Sustainability:

Chipboard is often made from recycled paper and is recyclable itself. The sustainability factor is crucial for companies looking to reduce their environmental impact. Many chipboards are manufactured using eco-friendly processes and materials.

Cost-Effective Option:

Chipboard is generally a cost-effective option compared to some specialty grades of cardboard. This can be an important consideration for businesses looking to manage packaging costs without compromising on performance.

It's important to note that the choice between chipboard and cardboard for slip sheets depends on the specific requirements of the application. The type of products being transported, the handling and storage conditions. Additionally, advancements in cardboard technology have led to the development of high-strength and moisture-resistant cardboard options that may also be suitable for certain slip sheet applications.